OPY 48V Solar Inverter Charger

|

Item

|

HF4830S60

|

HF4850S80

|

HF4835U60

|

HF4850U80

|

|||

|

Brand Name

|

OPY or OEM brand

|

||||||

|

Rated input voltage

|

220/230Vac

|

110/120Vac

|

|||||

|

Output voltage waveform

|

Pure sine wave

|

|

|

|

|||

|

Rated output power (W)

|

3000W

|

5000W

|

3500W

|

5000W

|

|||

|

Peak power

|

6000VA

|

10000VA

|

5000VA

|

7000VA

|

|||

|

Rated battery input voltage

|

48V (minimum start voltage 44V)

|

|

|

|

|||

|

Battery type

|

Lead acid or Lithium battery

|

|

|

|

|||

|

Charge voltage range

|

40 –58Vdc

|

|

|

|

|||

|

PV operate voltage range (Model L)

|

60-145Vdc

|

||||||

|

Max PV output power (Model L)

|

4200W

|

||||||

|

PV operate voltage range (Model H)

|

120-500Vdc

|

|

120-450Vdc

|

120-500Vdc

|

|||

|

Max PV output power (Model H)

|

4200W

|

5000W

|

4200W

|

5000W

|

|||

|

PV charging current range (settable)

|

0-60A

|

0-80A

|

0-60A

|

0-80A

|

|||

|

Communication interface

|

USB/RS485(WiFi/GPRS)/Dry node control

|

|

|

|

|||

|

Dimension (L*W*D)

|

426mm*322mm*126mm

|

|

|

|

|||

|

Weight (kg)

|

11kg

|

|

11.6kg

|

||||

|

Warranty

|

1 year

|

||||||

|

Delivery Day

|

3-15 days upon receipt of deposit

|

||||||

|

Shipping Way

|

Express / Air Shiping / By Sea / By Train

|

||||||

Main Featrures:

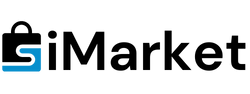

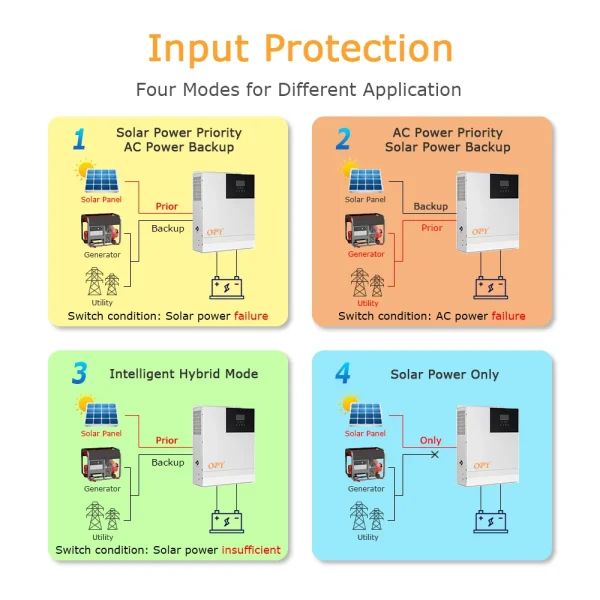

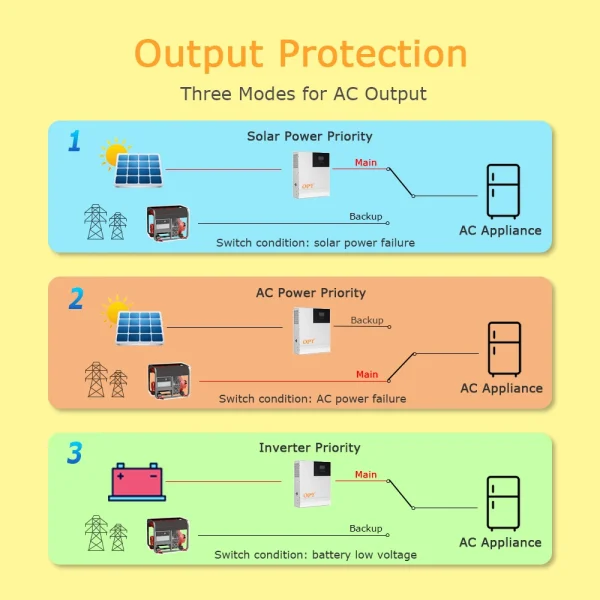

1. Pure sine wave solar inverter. 2. MPPT charger controller inside, efficiency ≥99.9%. 3. Flexible battery charging:

4. Two type output voltage:

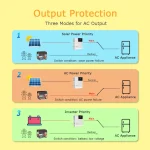

5. Support both lithium and lead acid battery. 6. Perfect protection. Undervoltage, short-circuit, overloading and backflow protection.

7. Wifi&GPRS available for mobile phone monitor.

Package Detail

2. User manual and accessories

3. Paper carton

PS: OEM customized Package is available

Shipping terms

1.Shipping out after finishing manufacture and received payment.2. Delivery time: 3-15 days against quantity and storage.

3. Flexible shipping way for you

A. Express by DHL/UPS/TNT/EMS/FeDex or special lines.

B. Air shipping is available to destination airport.

C. Sea shipping is available to destination sea port.

D. DDP by train or sea shipping to door.

Quality Assurance

1. 100% high quality electronic components:

Reject any recycled or regrind components.

2. 1st test by inspector before mass production:

Ensure each batch is qualified components.

3. 2nd test by QC to check after assembling:

If fail, return back to worker to repair at once.

4. 3rd test for functions by inspector before package:

Ensure all functions can work normally.

5. Paper box and carton to avoid unexpected damage in shipping.

6. 4th test by inspector for package quality before delivery.

Reviews

There are no reviews yet.